Supercritical foaming is a physical foaming process for plastics. Before getting to the benefits of what that means, it’s helpful to

understand the alternative: chemical foaming processes.

Chemical plastic foaming is arguably the most common technology used to create footwear foam today.

In this process, a chemical foaming agent (a.k.a. blowing agents) is injected into a polymer.

When heated together, the chemical foaming agent decomposes and releases gas into the mixture.

The gas bubbles create air pockets in the melted polymer to create a foam.

While cheap and very capable at their job, many chemical foaming agents bring along some baggage.

Some of it is early in the supply chain during the manufacture of the toxic chemical agents.

The rest is usually associated with inhalation risks, carcinogens, and the release of volatile organic chemicals (VOCs) during heating,

decomposition, and post-production off-gassing.

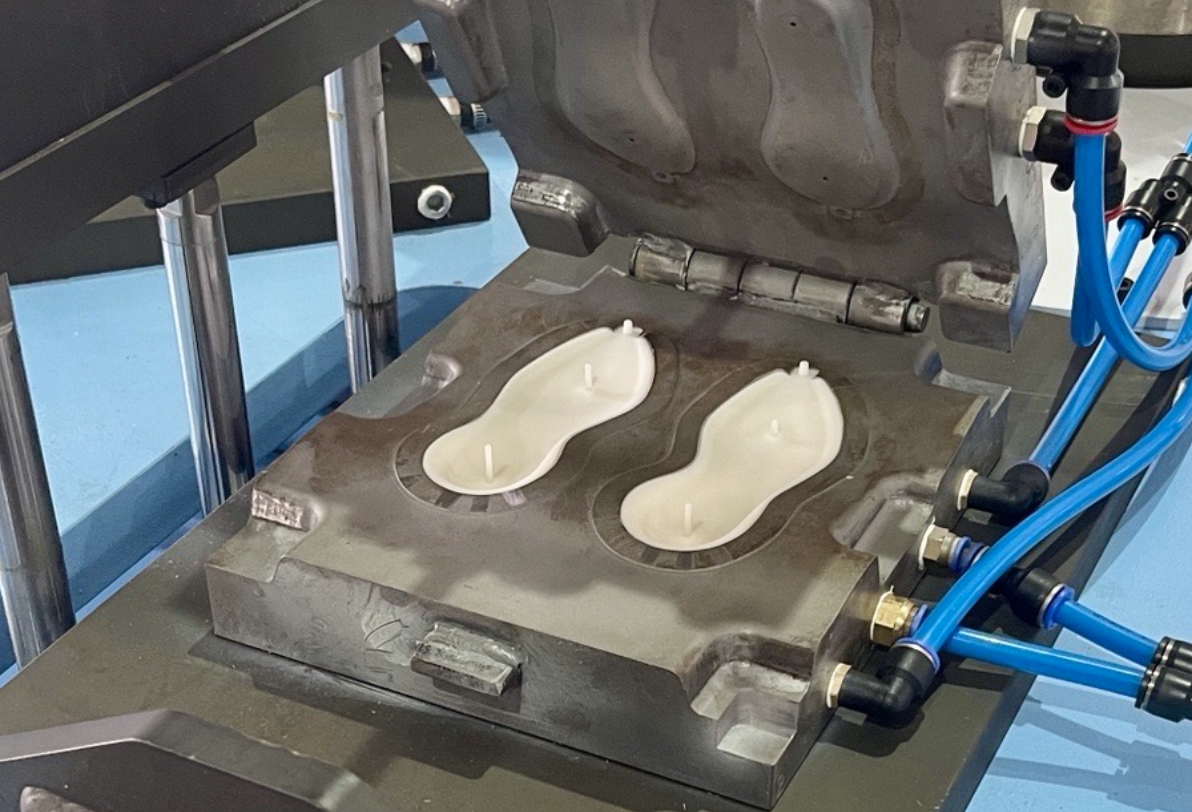

Supercritical foaming (SCF) skips the “chemical” part entirely and injects an inert, nontoxic gas–usually carbon dioxide or

nitrogen–directly into the melted polymer. With the right blend of heat, pressure, and mixing, a uniform and high quality foam

is the result. The Comfort and Performance Benefits of Supercritical Foaming.

Supercritical foaming creates foam with the following characteristics:

Lightweight

Small pore (air pocket) size and uniformity

Durable comfort

More stable performance

Contact: Sales Dept

Phone: 0769-86293481

Tel: 0769-86293481

Email: sales@smstechindu.com

Add: B2B Office: Fl4 HuaGu Building 3, BaoTang Road, HengKeng, LiaoBu Town, Dongguan, China

We chat